No-till and other reduced tillage systems continue to be touted as important and necessary practices to reduce nutrient and sediment losses from agricultural fields. Although no-till soybean production has flourished in most soybean-growing areas, no-till corn acres have not kept pace.

This is especially apparent in the northern Corn Belt, where yields of no-till corn have suffered in recent years. On heavy but highly productive soils in this area, cool, wet springs have created an adverse environment for corn establishment and early growth.

In residue-covered no-till fields, these effects have been magnified. Late-planting, reduced stands, poor early growth and delayed development have resulted in substantially lower yields compared to conventional tillage.

In areas where cool, wet soils predominate at corn planting time, an alternative to no-till production is needed. Many growers in these areas are trying strip-tillage, also referred to as zone tillage.

In this production system, a narrow strip 6 to 8 inches wide is tilled, which provides a residue-free zone for planting and emergence. The soil surface between the tilled strips, representing over 66% of the total field area, retains its crop residue cover, and with it, its soil conservation and water quality benefits.

Strip tillage is a crop production system that combines the soil warming and drying benefits of tillage with the soil conservation benefits of no-till. In this system, a strip 6 to 8 inches wide is tilled in the fall, and the remaining inter-row space (usually 22 to 24 inches) with its crop residue cover remain undisturbed.

Tillage is usually accomplished using a shank and knife to lift the soil and disk blades to contain the loosened soil and form it into a raised ridge or berm. In most cases, fertilizer is applied during this tilling operation. In the spring, the tilled strips dry out and warm up much like a conventionally tilled field. The planter units follow these tilled strips, dropping seeds into the center of the raised berm, and often applying additional fertilizer as well.

Strip-Till Equipment

A strip tillage implement consists of a heavy-duty toolbar with planter-like row markers and these major components:

- Row-cleaners to clear heavy residue

- Coulters to cut residue remaining over the tillage zone

- Anhydrous applicator-style tillage shank and knife assembly to loosen the soil to a depth of 4-8 inches. Tubes for P and K fertilizer and/or anhydrous ammonia application are usually included.

- A pair of disc blades (often called covering discs or disc closers) to capture the loosened soil and form it into a small ridge or berm

The number of shanks on the strip tillage implement must match (or be a multiple of) the number of rows on the planter. Growers discovered early on that building a raised berm was important, primarily in order to keep the planted row from depressing to below the remaining soil surface in the spring. Researchers recommend forming about a 4-inch berm in the fall, which will settle to about 2 inches by spring.

Some growers are opting to build their own strip-tillage implements, and others are taking advantage of the increasing number of options available from farm equipment manufacturers. In some cases, especially when piloting the system, the strip-till implement may simply be an anhydrous ammonia applicator with additional components attached.

Corn Yields With Strip-Till

Research studies from several states and Ontario that tested the yield advantage of strip tillage have been mixed. In some cases, yields have been superior to no-till and have even equaled conventional tillage yields. In other research studies, however, yields have been lower than those of conventional tillage, and no better than no-till yields.

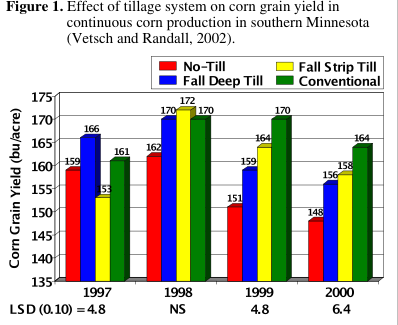

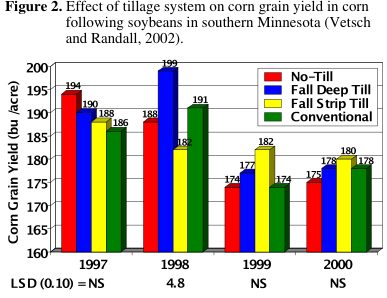

In many studies, the yield benefit depended on the growing environment, such that some locations and years were higher yielding, and others were not. A study conducted on a silt-loam soil in southern Minnesota (near Rochester) demonstrates this interaction of tillage system and year.

On continuous corn ground (Figure 1), fall strip tillage was higher yielding compared to no-till 2 out of 4 years, not statistically different one year, and lower yielding one year. Compared to conventional tillage, fall strip till was lower yielding 2 years and not statistically different in 2 years.

In corn after soybeans (Figure 2), tillage system differences were not significant 3 out of 4 years. In the other year, fall strip tillage was lower yielding than both conventional till and no-till.

In spite of mixed yield results, many researchers and growers are still optimistic about strip tillage systems, predicting that they will prove superior over time. When cool, wet seedbed conditions predominate, strip tillage should prove advantageous to no-till.

Research has shown that soil temperatures in fall strip tillage are often 5 to 10 degrees F warmer than no-till at planting time. Under field conditions that promote good emergence and early growth, however, little or no benefit is expected.

Latitude, prevailing weather patterns, soil type and amount and type of crop residue — for example, corn vs. soybean residue — are the primary factors affecting seedbed temperature and moisture in the spring. This may explain many of the mixed research results to date.

(Editor’s Note: This material is excerpted from article by Steve Butzen, Pioneer Hi-Bred agronomy communications research manager, which appeared in Pioneer’s Field Facts earlier this year.)

Post a comment

Report Abusive Comment