The following article is based on Rick Clark's presentation at the 2019 National No-Tillage Conference. To watch the presentation, click here.

Yield doesn’t drive Rick Clark’s no-till system. Instead, the fifth generation no-tiller intensely focuses on building soil health as the driver of his family’s 7,000-acre operation near Williamsport, Ind.

Farming with his father Richard and nephew Aaron, Rick’s diverse no-till system includes planting green and utilizing diverse plant species and rotations.

By focusing soil health, Rick says he knows higher yields will come later. And not only are yields more stable and projected to continue climbing, the Clarks have seen significant savings on their inputs — all while growing 100% non-GMO crops for a local dairy and moving towards organic production.

None of this would have happened without the status quo on the family’s farm. “I challenge everyone to get a little uncomfortable,” Clark told attendees at the 2019 National No-Tillage Conference. “I think you’ll like the way it feels.”

NO-TILL TAKEAWAYS

- To smother troublesome marestail or waterhemp, try seeding 120 pounds an acre of cereal rye and rolling it down to keep the weeds from germinating.

- Beef up your farm’s collection of on-farm data, if necessary, and use it to push your no-till innovation harder.

- Balansa clover has a hollow stem and may terminate better with a roller-crimper pass than crimson clover.

Pulling Up ‘Free’ Fertilizer

The Clarks’ journey to an advanced no-till system began 15 years ago when the family started no-tilling soybeans. Five years later they no-tilled their corn and added cover crops. Within 2 years they tried planting green into covers — a practice Rick says Mother Nature “shoved” them into one year when it wouldn’t stop raining and cover crops grew too big.

They thought it was going to be a disaster, but it wasn’t. They soon realized letting the cover crop grow longer they could maximize what the cover crop was intended to do, and they’ve continued the practice.

“We’re spending upwards of $25 an acre on a cocktail mixture. Why in the world would I want to go out on March 28 and burn it all to the ground?” Rick asks.

One of the biggest benefits they’ve reaped from planting green is sequestering more nutrients out of the soil profile. The Clarks have been able to fix upwards of 100 pounds of nitrogen (N) when the peas and clover in their oat-pea-clover mix survive the winter and continue growing until Mother’s Day, which is around the time he typically plants corn.

Tips for Choosing Non-GMO Seeds

and Diversifying Your Rotation

Click here to see no-tiller Rick Clarks’ thoughts on choosing the best non-GMO seeds for corn and soybeans and ideas to shake up your corn-soybean rotation with a little more diversity, whether or not you have livestock.

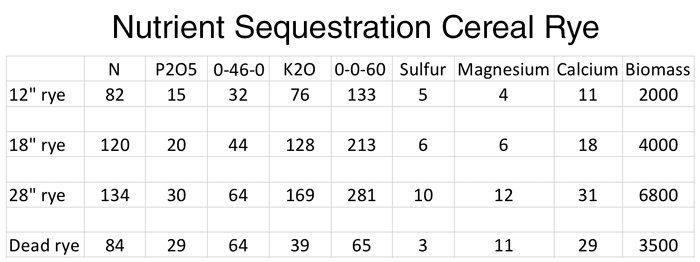

Biomass samples show the longer he lets covers grow, the more they’re able to sequester. Rick once took a 2-by-2-foot area of cereal rye at 12 inches, 18 inches and 28 inches tall, as well as dead cereal rye sampled two months after termination, to see just how many additional nutrients could be taken up by letting the rye grow longer (see Table 1).

TABLE 1. GREATER GROWTH, HIGHER SEQUESTRATION. Through biomass samples taken at the above growth heights, Indiana no-tiller Rick Clark saw just how many additional nutrients the cereal rye was able to sequester by allowing it to grow longer. (Note: Dead rye was sampled two months after termination in August.)

The 12-inch rye produced 2,000 pounds per acre of biomass and sequestered 82 pounds of N, 15 pounds of phosphoric acid (P205) and 76 pounds of potash (K20). But the 18-inch rye doubled in biomass and sequestered an additional 38 pounds of N, 5 pounds of P205 and 52 pounds of K20 per acre.

“Going from 12-inch rye to 18-inch rye in the month of April takes about 4 days,” Rick says. “If you wait 4 more days, look what we’re doing here.”

By letting the rye grow to 28 inches tall, it produced nearly 7,000 pounds of biomass and sequestered almost enough nutrients to fertilize Rick’s next cash crop for free: 134 pounds of N, 30 pounds of P205 and 169 pounds of K20.

“There’s thousands of pounds of these nutrients in the ground,” he says. “We just have to unlock it and get it up. We’re taking advantage of it.”

STP FOR PLANTING GREEN. Rick Clark is a big fan of Prescription Tillage Technology’s Sabre Tooth Planter (STP) double-disc openers for planting green because they eliminate residue hair-pinning and create a U-shaped furrow instead of a V-shaped one that lets Keeton seed firmers fit down in the furrow for better firming. The seedbed is also lifted and crumbled so that by the time the closing wheels reach the seed it’s already half covered.

As for the dead cereal rye sampled two months after termination, there was only 39 pounds of K20 left in it by Aug. 1, which means the rye had already released 130 pounds of K20 — more than enough for a soybean plant, Rick says. He notes that field also hadn’t had potash applied in 4 years, because it didn’t need any.

“You want to talk about farming in tough times financially,” he says, “how about saving some money on the input side?”

With the additional biomass the Clarks are producing by planting green, they’ve also been able to armor the soil for up to a year, which he says further protects it from erosion, feeds the soil microbes and suppresses weeds. Rick terminates his cover crops with an I&J roller-crimper, which is based on the one developed by Rodale Institute.

“Say you’ve got a marestail problem or a waterhemp problem. Plant 120 pounds of cereal rye and terminate it with a roller-crimper,” he says. “You won’t have those weed problems.”

He typically terminates his covers within 3-5 days after planting, but sometimes it may not occur for up to 30 days. Because he’s planting non-GMOs he must be careful about his timing in case he does need to use an herbicide.

On soybeans, he says glyphosate can still be used on the cover crops as long as the crop hasn’t emerged yet. And if the only cover crop grown is cereal rye, growers can still use Select.

DESTROYING THE TRENCH. Rick Clark found that Martin-Till’s Spader closing wheels and drag chain, coupled with Prescription Tillage Technology’s STP double disc open-ers, properly close the seed trench when he’s planting green, reducing seedling blight and increasing the number of harvestable plants. He wants the seed trench destroyed so that 4-5 days after planting, when the soil dries out, the seed trench won’t reopen and have high temperatures scorch the seed.

On corn, Rick admits he’s rolling the dice a bit because there is no herbicide that’s going to save him on any grass he has out there once the corn comes out of the ground, so he has about 5 days to make a decision.

“We have to be careful and we always have to be thinking forward,” he says. “What is the consequence going to be if I do this today? We always have to have that mindset.”

Good Data, Good Decisions

The Clarks are able to think through these situations and make the right decisions thanks in part to the data they’ve been collecting on their farm over the past two decades.

“I could tell you what was done on any particular field on our farm, whatever pass happened on our farm, for the last 20 years,” Rick says. “When you’ve got data like that, you’ve got a lot of power. Good data leads to good decisions.”

YEAR-LONG ARMOR. By planting green and then roll-crimping the cover crops, some-times the amount of biomass produced by the covers gives the Clarks’ soils up to 12 months of protection against erosion and weeds, while also continuing to feed the soil microbes.

That data has given Rick the confidence to implement practices that others would consider a recipe for disaster — such as planting corn after cereal rye. He starts with testing ideas out on a small area, about 20-30 acres, and replicating it again the next year. If it goes well, they’ll move it into production on the farm.

While cereal rye isn’t his first choice of cover crop species ahead of corn, sometimes it gets too late to plant a different cover crop and it’s the only option left.

“I’m more concerned about having a living, growing cover on my acre than leaving it naked, so I’m going to plant cereal rye if I have to, even though I’m going to plant corn the next year,” he explains, noting that he has his crop rotation planned out through 2023.

By doing some trials on corn after rye, Rick learned that it can be successfully done as long as he adjusts his N management.

For their operation that means broadcasting 150 pounds of urea, which provides enough N until he can apply more with Y-Drops at V8. The remaining amount he applies is based on soil nitrate tests. He takes 1-foot soil cores in both April and June, as well as 2-foot core taken at V8, which helps him see how the N is moving through the soil profile, if it’s stable, and what the N levels are so he can decide how much N the corn still needs.

Good data has also helped the Clarks avoid using many inputs. They don’t use any starter fertilizer, seed treatments, fungicides or insecticides unless absolutely necessary. This is partly because one third of the farm is being transitioned into organic production, but the primary purpose is to be better stewards of the environment.

“Say you’ve got a marestail problem or a waterhemp problem. Plant 120 pounds of cereal rye and terminate it with a roller-crimper and you won’t have those weed problems…”

For example, Rick stopped spraying pyrethroids because he learned that one pass of it will wipe out — at the minimum — 700 beneficial insects. Even when armyworms came in at V2 one year, he decided not to spray because he knew, based on his data, that the corn would recover within a week.

“They’ve mowed that field off,” he says. “That didn’t kill the corn. I’m not going to spray that pyrethroid and destroy everything else that’s out there.”

But Rick also realized he could adjust the timing of his planting to avoid armyworm damage in the first place. Working with a network out of Illinois, he puts armyworm and cutworm traps out in February, which helps the network track the pests’ flight patterns and density levels. Since they know the life stages of the armyworms, he asked himself, “Why don’t we time our planting based on the moth flight?”

ROLLING AWAY. Rick Clark uses an I&J roller-crimper to terminate cover crops 3-5 days after planting on his 7,000-acre farm near Williamsport in western Indiana. His preferred cover-crop mix for fields going to corn is haywire oats, Austrian winter peas, balansa clover, sorghum-sudangrass and daikon radish. Rick says balansa clover works better for rolling than crimson clover because its stem is about the size of a pinky finger and hollow, allowing for better termination.

Now, he plants so that when the corn emerges, the armyworms’ life cycle is on the decline, a period which varies year-to-year.

“When you have good data and you can make good decisions, your brain just relaxes because now you can think about things like that,” he says.

Choosing Covers and Rotations

The decision to reduce some chemical applications is another reason they began rolling and crimping their cover crops. Their goal is to reduce, if not completely eliminate herbicide use — but that means the Clarks must select cover crop species that can be terminated by the roller-crimper alone.

POLLINATOR PALOOZA. In pursuit of achieving balance in their no-till system, the Clarks created pollinator strips to provide a habitat for pollinators. Some strips are placed in the barrier the Clarks must have between their neighbor’s corn and their non-GMO or organic corn, while others are sometimes placed on the perimeter of soybean fields. They use a mix Rick Clark calls the “Pollinator Palooza” consisting of buckwheat, chickpeas, common vetch, flax, crimson clover, phacelia, rape, sunflower, lentils, yellow mustard, yellow sweet clover, radish, sunn hemp and peas.

Rick’s preferred cover crop mix for a field going to corn is 30 pounds of haywire oats, 5 pounds of Austrian winter peas, 5 pounds of balansa clover, 3 pounds of sorghum-sudangrass and 3 pounds of daikon radish.

He opts for haywire oats specifically because its branching provides more foliage growth in the fall, which protects the two legumes. He also uses balansa clover over crimson clover because its stem is about the size of a pinky finger and hollow, which allows for better termination with the roller-crimper.

Rick puts sorghum-sudangrass and radishes in every mix he uses, noting that the sorghum-sudangrass promotes mycorrhizal fungi growth better than any other cover crop he knows of. He wants the most diversification he can possibly have, not only with the species he’s selected but also diversification of annuals and perennials.

“You can fall into a monoculture in your cover crop program just like you can fall into a monoculture in a cash crop program,” he says. “Don’t do that. Be diversified.”

The Clarks also keep diversification in their cash crop rotation. One third of their farm is in a 3-crop rotation of corn, soybeans and wheat, while the last third is in a 4-crop rotation of corn, wheat, soybeans and alfalfa, which supplies a local dairy that is producing non-GMO milk for Dannon yogurt.

Clark says he puts wheat behind corn instead of soybeans is because he likes to plant his soybeans into the cereal rye at the boot stage, typically late April, then roll the rye when it’s reached anthesis. This means the soybeans are at the V2 growth stage and will also be rolled down with the rye — although the soybeans aren’t injured in the process.

Clark used to wait until rye reached anthesis and then plant soybeans, but that meant having to wait until early June. By planting soybeans at the rye’s boot stage he’s moved the planting date up 30-40 days, helping him get fall cover crops seeded earlier.

And Clark waits until the rye reaches anthesis to roll-crimp because that’s when the lignin in the rye stalk is at the highest level and becomes very brittle, so it’s easy to kill with the roller-crimper. This also lets him avoid spraying chemicals completely because the biomass of the rolled rye very effectively suppresses weeds — a key step in transitioning to organic production.

COCKTAIL BEFORE CORN. Consisting of haywire oats, Austrian winter peas, balansa clover, sorghum-sudangrass and daikon radishes, this cover crop mix, which Rick Clark calls the “Gunslinger,” is what he seeds in the fall in a field that will go to corn in the spring. The species in the mix will either winterkill or can be terminated by the roller-crimper.

But by waiting until anthesis, the cereal rye seed are viable, which would result in volunteer rye growing with the wheat. “Your elevator man is going to reject every load,” Rick says. “Do not plant wheat following a soybean crop that was terminated by a roller-crimper at anthesis.”

Rick speaks from experience on this, but fortunately he was able to supply that crop to the dairy as wheatlage instead. By growing wheat after corn he avoids this problem and simply adjusts his N management to accommodate following a grass with a grass, just like he does with corn after cereal rye.

Lower Costs, Higher Yields

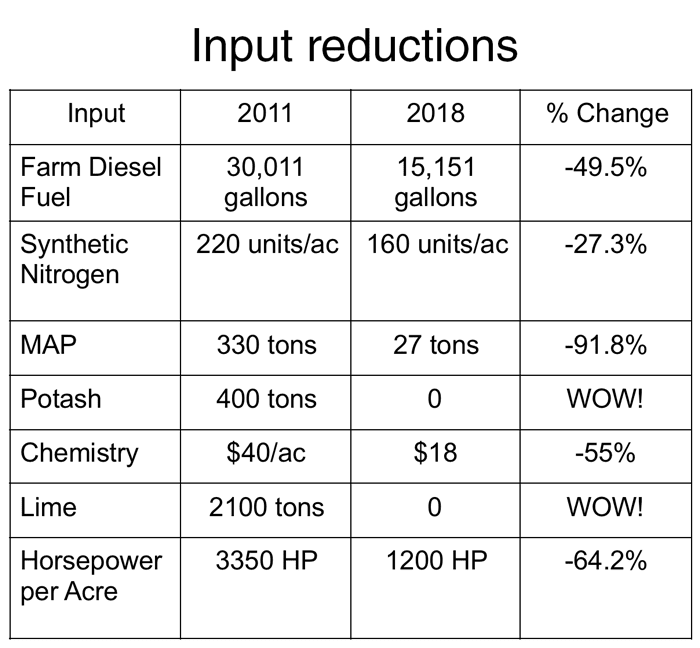

The combination of diverse species and rotations, along with planting green and avoiding chemicals, has resulted in some significant changes for the Clarks’ farm. And thanks to their commitment to collecting data they can see how the changes improved their bottom line (see Table 2).

TABLE 2. SIGNIFICANT SAVINGS. In 7 years, the Clarks have seen over 50% reductions on all of the above inputs except for synthetic nitrogen, which still saw a 27% decrease.

Just from 2011 to 2018 they’ve seen their fuel, synthetic N and MAP uses decrease by 49.5%, 27.3% and 91.8%, respectively. They went from spending $40 an acre on chemicals to $18, a reduction of 55%. And their horsepower requirements went from 3,350 to 1,200.

“Think about the amount of money that’s tied up in horsepower today,” Rick says. “You don’t have to have that.”

Finally, they’ve been able to cut lime and potash out of their system completely. “The average pH on our farm right now is 6.8,” Rick says, noting that he soil tests his fields every other year. “We haven’t applied lime for 3 years. That makes sense though, right? We’re not scorching the soil with chemicals and fertilizer.”

While high yields are not Rick’s main goal, but as a result of adding cover crops and improving on soil health, he says yields are more stable and tracking upward. Rick asked his nephew, Aaron, to review their crops’ yield variability before and after cover crops (see Chart 1). He found that before they started using cover crops, their corn yield varied by 28 bushels. After cover crops, it dropped to 4.7.

CHART 1. BETTER PREDICTIONS. Since implementing cover crops into their system, Rick Clark says that he’s in a position of power with marketing because his crop yields are very close to their expectations. Before, his corn and soybean yields varied by about 28 and 9 bushels, respectively.

“I’m in a position of strength,” Rick says. “I can now market my grain, barring any weather issues, if I feel like the market is at a point where I can pretty comfortably determine what my corn yield is going to be because of this, and I can forward sell grain.”

Aaron saw a similar situation with their soybeans. Before cover crops the yield varied by 8.8 bushels. Now it’s 2.75.

“There’s thousands of pounds of these nutrients in the ground. We just have to unlock it and get it up. We’re taking advantage of it…”

They also took trajectories of their corn and soybean crops and discovered corn is projected to increase 3.9 bushels per acre per year, while soybeans are projected to increase 1.3 bushels per acre per year, all while continuing to decrease their input costs.

Go Slow, Keep Trying

Rick admits his system didn’t develop overnight and what works on his farm may not be the best approach for someone else. But it doesn’t mean he wants no-tillers to feel completely comfortable with their operation and not try anything new.

“I can’t guarantee that you will have that same success, so please go slow, go easy and take your time. “What we’re doing here is pretty advanced stuff,” he says. “But if you’re not uncomfortable with what you’re doing then you’re not trying hard enough to change.”

Post a comment

Report Abusive Comment