In this three-part series, part one addressed water losses from a center pivot and when to replace an existing sprinkler package and part two focused on basic sprinkler package design.

The best height for sprinkler devices relative to crop height has been debated for some time and has recently resurfaced. Some have decided to reposition devices at the truss rod height back to atop the pivot pipeline because of the tall corn varieties being grown today. Others have opted to place sprinklers down in the canopy to try to “save” water. Keep in mind that transpiration is small while the canopy is wet from irrigation because evaporation is occurring from the canopy.

The challenges of getting good water application uniformity while preventing runoff or water moving within the field is greatly increased when sprinklers are placed in the crop canopy (Figure 1). The spacing needs to be close, 5 feet or less is best, but not more than 7.5 feet Many people today are using 30-inch spacing on the outside three or five spans. The added sprinklers will increase the package cost and require smaller orifices. If any sand or debris is in the water, it should be filtered before going into a pivot with small orifices to prevent plugging.

Pivots that will irrigate both corn and shorter crops like soybeans have an added challenge when determining the sprinkler height because of the vastly different heights and canopy structure.

In addition, producers can mitigate evaporation by selecting newer sprinkler devices that produce large or medium sized drops and then leave some crop residue on the soil to prevent surface sealing. Further mitigation can be achieved by keeping the wetted diameter of the sprinklers as small as possible without creating runoff. Thus, the comparison should always be between the best designed sprinkler package — either above- canopy or in-canopy — for a given field and specific location and your water supply.

Advantages for In-Canopy Sprinklers

Sprinkler packages in the crop canopy have an advantage over above canopy sprinklers by reducing evaporation and wind drift losses. Factors to consider include:

- Most wind drift lands in the field, but more of the canopy is kept wet, which increases net canopy evaporation losses.

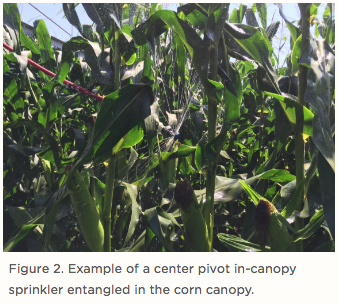

- The canopy may stay drier during irrigation, which would reduce but not eliminate canopy evaporation losses because when sprinklers drag through the canopy they tend to spray water vertically and often get much of the canopy wet (Figure 2).

- The benefits will be reduced for locations in the Eastern High Plains (i.e., east of Grand Island) because of higher humidities and smaller annual water requirements.

- The advantages will increase with the more arid environment farther west and south in the High Plains because of increased evaporative losses and larger irrigation requirements.

- The advantages will be larger for low capacity systems because they need to run more hours each year, increasing the opportunity for net canopy evaporation and drift. Runoff also will be of less concern for these systems.

- The advantage will be larger if the water source provides warm water from a canal versus cool water from a well.

- The economic advantage will be larger if the system capacity or water allocation is low enough that the reduced evaporation will increase yields and not just reduce pumping costs most years.

- The advantages will be larger if small frequent applications are preferred over larger less frequent applications.

- In-canopy packages are most feasible on level fields where runoff due to the increased water application rate caused by canopy obstruction of water jets occurs. Runoff is much more likely on fields with significant slopes.

- Some dealers and farmers do not like up-top sprinkler placement with high iron water due to the staining of the pivot and possible issues with alignment linkage at the towers.

- No-till usually results in higher infiltration rates and reduced runoff potential.

Disadvantages for In-Canopy Sprinklers

Sprinkler packages designed to operate in the crop canopy have several disadvantages over above-canopy sprinklers:

- The increased cost of closer spaced devices and longer drops.

- The sprinklers will drag back in the canopy resulting in the sprinkler spraying water vertically and not horizontally as designed, resulting in wetting of most of the canopy (Figure 2). Sprinklers also become entangled in the canopy and are frequently stuck in one location for several moves of the pivot lateral. The device simply lifts each time the pivot tower moves, but the device stays at the same radial point in the field. After several tower movements the devices dislodges from the canopy and swings below the pivot lateral, skipping over several feet of the row (up to six feet in some cases). The process is then repeated at the next location. Data does not exist to quantify the effect of this action on application uniformity and runoff problems, but the effect is significant and could affect crop yields or require more pumping too fully irrigate the crop—especially on sandy soils where lateral water flow is less and the soils hold less water. Some farmers use spray heads spaced at 30 inches in bubble mode to minimize canopy wetting, but runoff needs to be closely monitored.

- Planting in a circle will help keep the devices in the canopy, but many farmers prefer straight rows.

- Well water that is cooler than the dew point temperature of the air can lead to condensation of water from the air when droplets first travel from the sprinkler device. The droplets will warm during travel, but may experience condensation for a significant portion of the travel through the air. This increase will be small, maybe 1%, but it shows that droplet evaporation is insignificant for these conditions.

- Electric systems operating on load control are often shut down during the highest wind and evaporative time of the day. This point is not a disadvantage to in-canopy sprinklers, but it does lower losses for above-canopy devices.

- Greatly increased runoff potential, especially in systems with higher capacity.

- The smaller wetted radius will greatly increase runoff potential on sloping fields.

- Some sprinklers with moving parts can become jammed by plant material.

- The sprinklers and drop components can potentially have higher maintenance costs because they are dragging through the crop canopy, plus will get flopped around more by the wind during the off season, causing them to bang together and into pivot towers.

- The devices are out of sight, making it difficult to monitor problems during the season.

- The sprinklers need to wet the entire canopy for fungicide applications.

- The entire pivot should always be fenced off if cattle graze the field. Having long drops increases the importance of fencing.

- In-canopy sprinklers may require more management to get the desired results.

Design Considerations for In-Canopy Sprinklers

Based on our observations several practices can help improve the success of sprinklers placed in the canopy:

- Alternate drop tubes between the right and left side of the pivot by clipping the tubes to the truss rods can help reduce runoff potential by effectively decreasing the application rate.

- Clip drop tubes to truss rods appears to help keep devices in the canopy.

- Consider limiting system capacity to 4 to 5 gpm/acre to help prevent runoff.

- Space sprinklers at 40 inches or less on the outside three to five spans. Often spray heads with bubble capability are used with narrow spacing.

- Manage orifice size is an important part of designing a close-spaced package. A good design will use wider spacing on the first span (90 to 120 inches) with sprinklers mounted at truss rod height, then 60 inches on the next span or two until an orifice size can be achieved that has little potential to plug when the spacing is narrowed to 30 inches. Other than the first span, sprinklers are often mounted at two or five feet. Many designers do not like to go smaller then a 3/32-inch nozzle to help prevent plugging.

- Use more streamlined, smaller diameter sprinklers to improve movement through the canopy.

- Consider sprinklers that vibrate, like the Orbitor, which appear to reduce entanglement and help keep devices down in the canopy.

- Use extra weights and mount them as close to the bottom of the sprinkler as possible to help keep devices in the canopy.

- Consider using sprinklers with moving pads rather than stationary spray pads as they seem to provide better water penetration through the canopy.

- Avoid sprinkler placement at corn ear height where the canopy is most dense, making it difficult to distribute water to adjacent rows.

- Set sprinkler mounting height for short-dense crops like drilled soybeans high enough to keep the device above the canopy. Consider a minimum of 5 feet.

Post a comment

Report Abusive Comment