For 30 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The products selected save producers time, reduce costs and labor, all while improving user safety.

To be eligible for the award, each development — which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the whole industry, not just to an individual company. In addition, for the 2017 awards the development must have been first made available for purchase or ordering during the 2016 calendar year.

Each year an international panel of industry experts in technology, design and product development evaluate the entries and select up to 50 products for recognition.

Below you will find several of the winners of this year’s AE50 Awards.

Woods 30 & 40 Series Rotary Tillers The Woods 30 and 40 Series rotary tillers are 3-point mounted, gear-driven tillers designed specifically for small-acreage farming and gardening. A unique double-flange rotor design was developed for these forward and reverse rotating tillers, which incorporates a single bolt that positions the tiller blade at the proper orientation for engaging the soil. The double-flange design creates two shear planes in the bolted joint, which reduces the load on the bolt by half when compared to existing single-flange designs. This design is advantageous in reducing assembly and service times by as much as 50% and providing a more durable product to the customer. This approach in attaching the tiller blade to the rotor shaft makes domestically manufactured components more competitive in a price-driven global market. Blount International Inc., Oregon, Ill. |

De Bruin Engineering Integrated Harrington Seed Destructor The Integrated Harrington Seed Destructor, or iHSD, is an innovative weed seed management product that mechanically destroys weed seeds at harvest time. The iHSD is installed on and powered by a combine. Once the grain is separated, the chaff containing standing weed plants is processed through an impact mill that results in up to 99.8% destruction of specific weed seeds. Importantly, this process is non-selective to herbicide-resistant weed species. The benefits of using it in continuous cropping operations include reduced overall emerging weed numbers and decreased populations of herbicide-resistant weeds, resulting in lower volume, fewer spraying treatments and fewer chemical herbicide groups. Organic matter is returned to the field and retained, resulting in healthier, more productive soil and reducing the need for supplemental phosphate, nitrogen and potassium applications. The iHSD can be fitted to an expanding range of combines. De Bruin Engineering, Mount Gambier, Australia |

MacDon M1240 Self-Propelled Windrower Tractor The MacDon M1240 Windrower provides increased speed and improved ride quality with patented CrossFlex suspension. To obtain higher speeds without sacrificing low-speed torque, the windrower varies the displacement of the wheel motors electronically. This leaves the operator with full available wheel motor torque at low speeds, combined with the ability to reach road speeds without the need to shift speed ranges. The 248 horsepower Cummins engine uses dual radiator cooling that draws air from the cleanest location, behind the cab. To keep the clean air flowing constantly, a hydraulic-drive reversing fan blows out unwanted debris on the go, without the need for operator input. An all-new One-Touch-Return preset system allows the operator to adapt to changing field conditions with the push of a button. MacDon Industries Ltd., Winnipeg, Man. |

Kopper Kutter ARRO Conversion for Corn Heads to Harvest Sorghum The ARRO Alternate Rotary Row-Crop Option from Kopper Kutter consists of a conversion kit for existing corn heads so they can harvest additional crops including sorghum (milo), sunflowers, millet and some cellulosic crops. The reconfiguration kit uses simple sprockets driving the dual disc cutters. It can be installed on reliable base corn heads, preferably those that have been used for a few seasons and have worn stalk rolls and deck plates. These used corn heads already have individual row unit slip clutches, enclosed gear case drives and poly divider shields and points, along with reliable (optional) header height control systems. A benefit of the ARRO head is the long poly points that can lift lodged crops. The higher cutter positioning on the topside of the frame leaves over 10 inches of stalk remaining in the field. Kopper Kutter LLC, Cimarron, Kan. |

Tribine Harvester The Tribine Harvester is a 4WD grain harvester with a high-capacity threshing and separating front module that is connected by articulation joint to a large 1,000 bushel capacity grain tank on the rear module. By removing the grain tank from the top of the processing unit and removing the guide axle from beneath, the Tribine achieves a new architecture that allows for significant gains in harvesting throughput to accompany the on-board grain tank. The unit features a 38 inch diameter rotor (for increased threshing capacity) underlain by a 103 inch wide cleaning system. On each side of the large rotor is one of two engines that power the unit, giving great weight balance and limitless total power combinations for the harvester’s future. The 40-degree articulated steering, combined with another 22 degrees of rear axle steer, allows the machine to turn tighter than other current combines. Tribine Harvester LLC, Newton, Kan. |

Appareo Gateway 300 Advanced Computing Platform Gateway 300 is an all-in-one global control, monitoring and telemetry solution, equipping motorized farm vehicles with terrestrial and satellite communication connectivity capabilities, enabled by the global Iridium satellite network. Appareo designed this computing platform to provide a wide range of communications technologies, including Wi-Fi, Bluetooth, cellular, GPS, 433 MHz, CAN and Iridium satellite. Gateway 300 is built with a rugged enclosure for outdoor use and for mounting on heavy machinery. The device can collect and distribute real-time data, product and performance data, health and asset management data, location data and security and recovery data, in addition to remote diagnostics and the possibility for future predictive maintenance capabilities. The benefit to farmers is greater uptime for their machines, more optimized use of their machines, and less time and energy required to manage the service and maintenance of their machines. Appareo, Fargo, N.D. |

AGCO Challenger 1000 Series Designed to deliver lower cost of ownership and improved productivity per acre, the Challenger 1000 Series tractors allow producers to invest in a machine that can serve multiple needs. These compact fixed-frame tractors with flexible ballasting options are designed to prepare an operation for the needs of tomorrow, as producers need to cover more acres in less time, and compete one-for-one on efficiency and cost of ownership with any comparable tractor. The 1000 Series tractors combine the power of a small frame, articulated 4WD tractor with the flexibility and speed of a lighter weight, fixed-frame row crop machine. This allows maximum utilization from spring to fall without the need for two tractors to perform row-crop and heavy tillage work. The Challenger 1000 Series includes four models ranging from 396-517 engine horsepower with a weight range of 31,204-50,706 pounds. AGCO Corp., Duluth, Ga. |

Case IH Tiger-Mate 255 Field Cultivator The Case IH Tiger-Mate 255 Field Cultivator is a rugged and productive seedbed preparation tool that creates a high efficiency seedbed for the most accurate seed placement. The new Advanced Conditioning System with TigerPaw Crumbler has an easily adjustable front spike bar to optimize leveling and residue flow for various conditions. The frames are designed with high strength-to-weight ratios for maximum durability while minimizing unnecessary compaction. The tire offering includes stubble-resistant radial tires that prevent downtime due to tire failures and reduce compaction by up to 24%. The wheel retraction feature allows the wing wheels to automatically retract during folding, which results in a narrow transport size. The 10 mph maximum operating speed results in a 25% increase in productivity compared to traditional field cultivators of the same size with 8 mph speed limit. The Tiger-Mate 255 is available in working widths ranging from 22-60 feet. Case IH, Racine, Wis. |

TeeJet TTI TwinJet Spray Tip The TTI60 TeeJet twin flat spray tip provides large droplets for maximum drift control along with the improved coverage of a wide-angle twin spray. By using existing air-induction spray technology in a new configuration and with new geometries optimized specifically for creating Ultra Coarse droplets across the majority of the recommended operating range, TeeJet Technologies has improved spray application coverage while maintaining superior drift reduction in comparison to conventional spray nozzles. Twin style flat spray tips are best suited for broadcast spraying where superior leaf coverage and canopy penetration are important. The single-piece tip and cap design allows for easy installation and, unlike some other twin sprays, has a very compact size. The TTI60 is ideal for the application of systemic, post-emerge herbicides. The drift control makes it ideal for operating near sensitive areas such as susceptible plants, open water or residential areas. TeeJet Technologies, Wheaton, Ill. |

Anderson Group Pro-Chop 150 Bale Processor The Pro-Chop 150 bale processor from Anderson Group is a bale blower with a new modular chopper system. The chopper system is easily adjustable to the optimal cutting length for each use (bedding or feeding) and material (straw, hay or haylage). This system is a combination of a new rotor equipped with 264 aggressive knives, a top gate that helps chop fiber when engaged, counter-knives that chop finer when used along the top gate and a removable recutter screen with 2 inch holes that force longer fibers to be recut. The flexibility in cutting length (from no cut to 1 inch) and ability to process all fodder types is unique. A conveyor and comb allow bales to be fed perfectly through the rotor, preventing blockages. The 68 inch diameter blower can spread up to 52 feet and the 5 foot wide chamber is ideal for all round and square bales. Anderson Group Inc., Chesterville, Que. |

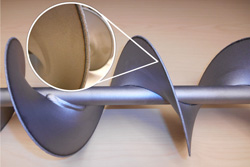

Kondex ToughFlight Auger Kondex Corp.’s patented laser-clad ToughFlight augers feature proprietary Tungstrong laser cladding on the leading edge of the auger flighting. This tungsten carbide application provides a wear coating that extends the life of the product and prevents grain pinching and damage when used in grain handling applications. The result is better grain quality, and thus better payout to the producer. Unlike other high-wear material applications, laser cladding creates a true metallurgical bond between the substrate and the tungsten carbide powder matrix, preventing it from chipping off while minimizing the heat-affected zone and product distortion during application. The auger also combats wear at its origin through its leading edge application, whereas alternative high-wear augers with additives on the flighting surface will continue to lose material from the outside edge in. The result is significantly greater product life and a better-performing auger that prevents crop trapping. Kondex Corp., Lomira, Wis. |

Laforge Guided Hitch for Pull-Type Implements The Laforge Guided Hitch allows a semi-mounted (2-point) planter or applicator to follow the tractor’s RTK guidance line with a high level of accuracy on flat fields and on hillsides with up to 13% slope. The compact design with linear side-to-side movement of the guiding element guarantees more responsive control of the implement and less impact on the tractor’s yaw movement compared to other designs, especially under heavy loads. Automatic Guidance with the Laforge Guided Hitch brings the planter or other implement to the same accuracy as the tractor for precision placement of seed and nutrients in separate passes. The basic design replaces the factory crossbar on John Deere’s planters, and adapters for several strip-till implements and nutrient applicators are available. It was developed in collaboration with John Deere as an Allied Product. Laforge Systems Inc., Concord, Calif. |

John Deere 9009A Terrain Cut Rotary Rough Mower The 9009A TerrainCut Rough Mower is a five-gang, 27 inch independent rotary deck mower with a 9 foot cutting width. The deck allows quick, tool-free height-of-cut adjustment, and the asymmetric rear discharge minimizes the need for blowing and dispersing clippings. The 9009A traction system with a standard eHydro traction pump, wheel motors and internal wet disc brakes maximizes performance on undulating terrain while eliminating adjustments and linkages. Operator improvements include AutoPedal, which controls engine rpm and transport speed through the eHydro foot pedal. The TechControl display on the command arm allows the operator to electronically set mowing and transport speed, and control turning speed, deck drop rate and weight transfer. The display also engages the LoadMatch power management feature, which automatically adjusts the machine speed to power the cutting deck to maintain cut quality in heavy load conditions. John Deere, Moline, Ill. |

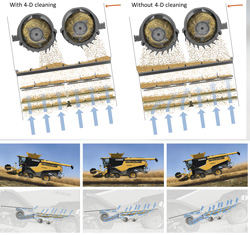

Claas 4D Cleaning Claas’ 4D Cleaning is an automatic, multi-directional system that compensates for the combine’s side roll when harvesting on a cross-slope and for the combine’s fore or aft pitch when harvesting uphill or downhill. As the combine leans, the rotor cover plate’s axial louvers angle away from the slope, optimizing the distribution of material passing out of the separation rotor grates onto the rotor returns pan to prevent material build-up on the low side and overburdening the low side of the cleaning shoe, which can cause increased grain loss. When harvesting downhill, the cleaning fan reacts automatically to the forward travel angle of the combine by increasing speed to prevent material build-up in the front area of the cleaning system, and it slows when the combine harvests uphill, as well as opening the lower sieve automatically, allowing grain to pass through the sieve more quickly to minimize the potential for loss. Claas of America Inc., Omaha, Neb. |

Capstan Ag Systems N-Vision Anhydrous Ammonia Sentry N-Vision carefully monitors every drop of anhydrous ammonia, providing a detailed, real-time look into the tank and plumbing to provide vapor-free liquid to metering and distribution devices. It allows operators to determine exactly when the tank and plumbing capabilities are being overrun, as well as when the tank is truly empty, by actively maintaining a preset liquid level. This in turn allows the operator to make informed application decisions. These decisions garner confidence in application quality with the ability to use more of the anhydrous ammonia in each tank, the company says. Instead of leaving a remaining “buffer amount” in the tank, the entire tank volume can be used, resulting in improved productivity, which enables greater efficiencies in nitrogen distribution and tendering times. Capstan Ag Systems, Topeka, Kan. |

Summers VT Flex Applicator The patent-pending VT Flex Applicator from Summers Manufacturing is a fully customizable fertilizer applicator that precisely places up to three products (dry, liquid and NH3) at high speeds and can be set to 15, 20, 22 or 30 inch row spacing. The coulter blades and application knives can be configured to unique residue management needs. Users can choose between five coulter blade options (coulter spacing can be set for on-row and mid-row) as well as customizable application knives and levelers. The system allows operating speeds of 6-8 mph with dry application rates of 600-700 pounds per acre. The VT Flex Applicator is liquid ready and can accept practically any tank setup. Summers Manufacturing, Devils Lake, N.D. |

Dickey-john Mini GAC 2500 Grain Moisture Analyzer The Dickey-john mini GAC 2500 is the only handheld moisture tester that uses 149 MHz/UGMA technology for grain moisture analysis. The benefit to producers and seed companies of this new technology is that the mini GAC 2500 will consistently match the new UGMA moisture testing at the elevator. Using 149 MHz/UGMA technology provides farmers with control and accuracy not achievable before with a handheld tester. Capturing data and calibrating equipment, such as harvesting equipment, makes this new development a necessity. Dickey-john’s “Moisture Manager,” a new mobile app, gives farmers greater control of data capture and transfer, resulting in improved grain moisture decisions. Dickey-john, Auburn, Ill. |

Global Industries Ezee Dry The new Ezee Dry system includes a completely new plenum, bin structure and control system for fully automated grain drying with up to 25,000 bushels of storage capacity. The Ezee Dry system operates by filling the plenum in the upper part of the bin with wet grain. Fans push heated air into the bin below the plenum and through the wet grain. When the grain is dry, the system dumps the grain into the bottom of the bin, where an aeration fan cools the grain. The heat recovered from the dried grain helps dry the wet grain in the plenum. The control system makes the entire system fully automated by moving wet grain to the Ezee Dry, drying the grain and then moving dried grain to a storage bin. The system can be set up to dry grain in continuous flow, automatic batch or manual batch operation. MFS/York/Stormor/Brownie Systems, a Division of Global Industries, Grand Island, Neb. |

Sukup Mixed-Flow Grain Dryer The Sukup Mixed-Flow Grain Dryer combines the use of mixing/heating chambers with vacuum cooling technology to produce a dryer that removes moisture from grain more evenly and economically than other dryers. The vacuum-cooling system recycles warmed air back into the dryer, which reduces the amount of fuel needed to reach the optimum drying temperature. Fuel savings may exceed 25% compared to traditional pressure-cooled cross-flow dryers. The mixing chambers allow more uniform drying of grain, and they are made of solid sheets instead of perforated material, which eliminates the need to sweep debris from hard-to-reach upper screens on traditional cross-flow dryers. The patent-pending design of the Sukup Mixed-Flow Grain Dryer allows for a single center unloading system, compared to two in competitors’ mixed-flow dryers. This new dryer can be ordered with gravity-flow or auger loading and with auger or drag conveyor unloading. Sukup Manufacturing Co., Sheffield, Iowa |

Kubota RTV X1140 Utility Vehicle The new Kubota RTV X1140 Series of utility vehicles provides customers with significant enhancements in comfort and performance, building on the reputation of the RTV series. The new K-vertible Cargo Transformation System allows the RTV X1140 to be converted between 2-passenger and 4-passenger configurations in less than a minute while still allowing easy access to the cargo bed. In 4-passenger configuration, the X1140 has 9.9 cubic feet of cargo space, converting to 19.1 cubic feet in 2-passenger configuration. The integration of four-wheel independent suspension coupled with the reliability of the 24.8 horsepower Kubota diesel engine and the exclusive two-range VHT-X variable hydraulic transmission make the RTV X1140 dependable and smooth-riding, while the ROPS and cargo bed transformation system make the RTV X1140 unique in the industry, the company says. Kubota Tractor Corp., Torrance, Calif. |

Additional winners from the AE50 awards

John Deere F4365 High Capacity Nutrient Applicator

The F4365 High-Capacity Nutrient Applicator features a dual C-channel frame and parabolic leaf springs and shocks that provide a 30% better ride quality than the leading competitor while reducing operator fatigue and improving machine reliability. The CommandView III cab with the new Generation 4 CommandCenter display is tailored to dry application operators to make setup, operation and adjustments easy to complete. The Final Tier 4 9.0 liter engine with 400 peak horsepower coupled with the Infinitely Variable Transmission (IVT) allows spread speeds up to 30 mph and transport speeds up to 46 mph. Multiple dry spinner spreader options are available, allowing variable-rate spreading of up to four products. Paired with the 4 Series Sprayer line-up and the latest technologies from John Deere, including AutoTrac, John Deere Section Control, JDLink, Wireless Data Transfer, and AgLogic, the F4365 can maximize productivity throughout the spreading season.

John Deere, Moline, Ill.

Acclima TDR-315L Low Power Consuming Digital Time Domain Reflectometer/Soil Condition Sensor The TDR-315L is an integrated, waveform digitizing, true time domain reflectometer that uses high-speed electronics to bring this device down in price by about 25% from its predecessor, and up to 20 times less than it competitors. It has also halved its predecessor’s power consumption. This device accurately measures soil water content (even in saline soils out to 4 dS/m bulk EC), soil temperature, soil (bulk) EC and soil pore water EC. The TDR-315L is a SDI-12 compatible sensor, which makes it a critical component for logging soil water content in SDI-12 moisture monitoring systems. It will work with numerous third-party SDI-12 data loggers as well as with Acclima’s own DataSnap data logger. This newer and more accessible technology will have profound ramifications for researchers and farmers alike in terms of learning how to save water and fertilizers while increasing crop quality and yields, the company says. Acclima Inc., Meridian, Idaho |

Forest Concepts Crumbler M24ci ChipMuncher The Crumbler M24ci ChipMuncher machine is an industrial pilot-scale rotary shear designed to process up to two green tons per hour of raw biomass into precision, flowable particles for producing energy pellets, biochemicals, biofuels and other bioproducts. Size reduction by hammer milling, the previous industry standard, requires the inefficient drying of biomass to less than 10% MC because it does not work with high-moisture feedstocks. The Crumbler M24ci is unique in that it processes feedstocks with moisture levels ranging from 10% to more than 80% using very low energy and without the need to pre-dry. PLC controlled, the Crumbler can economically process a variety of raw materials, including wood chips, corn stover, switchgrass, bamboo, sage and others into highly uniform particles down to 2 millimeters in size that can optimize conversion efficiencies. Forest Concepts LLC, Auburn, Wash. |

SpectroCLick AAH-300b Absorption/Reflectance Visible Spectrometer The AAH-300 is a visible spectrometer coupled to a cloud back-end to allow ad hoc measurement of minor and trace chemicals of importance in agriculture for screening purposes. Personnel trained at the point of use, employing QR-coded reactant packets synchronizing human, instrument and data reduction activities, can screen for environmental, economic or yield-enhancing materials using an instrument that is fundamentally rugged and inexpensive because many functions previously achieved through precision hardware are now performed in software. While the current product provides absorption and reflectance spectrometry with a dedicated camera, the technology should easily transfer to smartphone cameras, further reducing cost and enhancing portability. Applications include optimizing fertilizer use to control costs and environmental impact, detecting the levels of desirable bioconstituents and screening for toxins, impurities or contaminants. Data is automatically archived in the cloud, establishing a chain of custody while maintaining confidentiality. SpectroClick, Inc., Champaign, Ill. |

John Deere MaxEmerg 5e Planter Row Unit The MaxEmerge 5e row unit uses a single electric motor to control John Deere’s MaxEmerge 5 seed meter with the traditional seed tube offered on many planters at a lower price than ExactEmerge. MaxEmerge 5e row units include many features found on ExactEmerge, such as curve compensation, vacuum automation, SeedStar 3 HP, and RowCommand. In addition, MaxEmerge 5e row units allow many options to be factory installed that used to require time-consuming installation by the farmer or dealership. These options are all integrated into the SeedStar 3 HP monitoring system and include individual row hydraulic downforce (IRHD), pneumatically controlled row cleaners, SeedStar Mobile and more. With SeedStar3 HP and MaxEmerge 5e, farmers can run their planters statically to tune the meters before working in the field. MaxEmerge 5e planters also support JDLink, allowing remote diagnostics to keep farmers in the field during the ideal planting window. John Deere, Moline, Ill. |

Oxbo 9220 Coffee Harvester The Oxbo 9220 Coffee Harvester is a completely redesigned machine based on a previous successful version. The machine now has a taller picking tunnel to accommodate the plantation-style trees now common in the coffee industry. The capacity of the lower conveyors has increased 25% and the capacity of the elevators has increased 100%. The plastic bucket elevators have been replaced with simpler paddle elevators. The cleaning system, adapted from proven vineyard technology, is new to the coffee industry and demonstrates more efficiency and capacity than previous designs. The large on-board storage bin can unload on the go, another new concept for the coffee industry. These features allow the Oxbo 9220 to harvest faster and produce a cleaner product than previous models. Growers have commented that the coffee is easier to process due to less trash in the fruit, and operator comfort is improved with the new air conditioned cab. Oxbo International Corp., Lynden, Wash. |

Irrigation Assn. Tree Drip Calculator Tree Drip Calculator (TDC) is a soil physics-based tool for designing and operating drip irrigation systems for trees. Previous design guidelines were manufacturer-specific and based on empirical data; this tool is based on USDA-ARS soils data and specifications of ANSI/ASABE Standard S623 and guides the designer in fully specifying design parameters, including emitter flow rate, emitter spacing, emitter placement and run-time. Run-time must enable the system to meet crop evapotranspiration and wetted area requirements and not lead to deep percolation. TDC guides the designer through complex interactions of design parameters, soil type and run-time, giving the designer operational results of particular parameter selections. TDC warns the designer if certain design conditions are not met. TDC helps the designer specify the system, and guides the irrigation manager in system operation. Irrigation Assn., Fairfax, Va. |

John Deere 500D Draper Platform The 500D Draper Platform is a new addition to the John Deere windrower product line. This family of products is compatible with W235 and W260 self-propelled windrowers and allows farmers to use the same traction unit for both rotary and draper heads. Farmers can switch between rotary and draper heads on a single traction unit in 30 minutes or less. The 500D is available in three models: the 25 foot 525D, the 30 foot 530D and the 36 foot 536D. These products are engineered for high-performance reliability, and all header functions are controlled with the Hydro Handle in the cab. The 500D Draper Platform enables greater productivity through center-driven belts and uses hydraulic pump control logic to deliver a constant header speed for more uniform cut quality and windrow formation. An improved reel increases durability in heavy crop conditions and includes quick-replace reel teeth. John Deere, Moline, Ill. |

New Holland T7 Heavy Duty Enhanced Engine Brake The T7 Heavy Duty features an enhanced engine brake system designed to absorb additional kinetic energy when compared to a conventional design. Dissipating energy with an effective engine brake reduces the burden placed on the tractor axle or trailer brakes, especially while descending long gradients. When activated, the engine’s electronic control unit cuts the fuel injection and closes a valve in the exhaust manifold. The resulting backpressure generates a negative torque. This is increased significantly on the T7 by using the electronic variable-geometry turbocharger to automatically maximize the manifold pressure. Additional braking effect has been added by incorporating a new variable-pitch cooling fan into the system. The fan vane angle adjusts when the brake is used to deliver maximum airflow, increasing the energy required to rotate the fan. The combined effect generates up to 140 horsepower of braking effort from the engine brake system. New Holland Agriculture, New Holland, Pa. |

AGCO Opti-Ride Active Cab Suspension The Opti-Ride Active Cab Suspension system benefits from the use of components commonly used by premium truck manufacturers in their cab suspension systems. Massey Ferguson has adapted these proven components for use in agricultural conditions for the MF 6700S Series. The conventional spring and damper unit, as used in mechanical cab suspension systems, has been replaced with dampers that are controlled by proportional electro-magnetic valves. These valves are controlled electronically and take into account the travel speed, acceleration and braking as well as the chassis size of the tractor. The Opti-Ride Active Cab Suspension system is thereby able to compensate for different operating conditions, such as in-field vs. road operation, and when taking corners. AGCO Corp., Duluth, Ga. |

John Deere 5G Series Tractor for 2017 The new 5G Series tractors offer a variety of configurations to maximize productivity in constrained environments. For narrow row crops, viticulture and orchards, the 5G delivers 75-100 horsepower within a minimum operating width of 39 inches, coupled with a turning radius of 11.9 feet. The Intelligent Power Management option senses when the tractor is being used for heavy PTO work and delivers up to a 9.9% power boost to improve productivity. For improved efficiency, the Economy PTO option allows a 15% reduction in engine speed for light PTO work, yielding reduced fluid consumption. The 5G offers a rear hitch lift capacity of up to 4,400 pounds, a 29% improvement compared to the prior 5EN model. The 5G is also one of the first products for the specialty crop segment that fully meets Tier 4 Final emissions requirements, with all after-treatment devices fully enclosed. John Deere Seeding Group, Moline, Ill. |

Sukup Zero-Entry Commercial Paddle Sweep The Zero-Entry Commercial Paddle Sweep is a grain unloading machine that sweeps grain from large bins without requiring the operator to enter the bin. The sweep’s A-frame design provides horizontal rigidity that prevents the sweep from bending as it moves through grain and vertical rigidity that allows use in deeper grain. The A-frame design also helps prevent stalling in the event of a grain avalanche. Vertical loads on sweeps in large bins may exceed 5,000 pounds per square foot, requiring tremendous design strength to endure such heavy loads. There are three major benefits of this product: safety is vastly improved because the sweep is operated entirely from outside the bin, its patent-pending design allows it to be used in deeper grain than other sweeps, and its paddles provide a cleaner sweep than machines using augers, thus saving on labor costs. Sukup Manufacturing Co., Sheffield, Iowa |

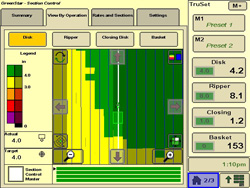

John Deere TruSet Tillage TruSet Tillage now allows producers to benefit from expanded functionality with documentation and prescription features. Documentation of a tillage pass now provides producers a historical record of jobs performed by mapping implement data of tool depth or pressure based on GPS location. With this information, producers can analyze the impacts of a job performed on their fields, enabling them to make decisions on their next pass. Prescription functionality will give producers the capability to pre-map the settings for a tillage machine, ensuring that operations are executed correctly based on location. Both the documentation and prescription aspects of TruSet can be performed on up to four functional areas, depending on the implement. These two additions to the TruSet Tillage system allow producers to optimize their crop production cycle and maximize return on their tillage investments. Deere & Co., Moline, Ill. |

Sinclair Print on Demand Sinclair Print on Demand allows packinghouse customers to print produce labels at the point of application and thereby reduce multiple label inventories and improve packing efficiency. The Print on Demand system prints GS1 DataBar codes, PLUs, fruit variety, lot numbers, and any combination of images or data that uniquely identifies attributes associated with loose produce. The previous requirement for multiple label designs is reduced to a single design with variable data printed in a blank area. Direct thermal print technology integrated with precision stepper motor control and Sinclair’s bellow application technology provides exceptional print quality while maintaining high label application rates. With the largest portfolio of label shapes, sizes and features in the produce labeling industry, Sinclair Print on Demand meets all of the industry’s labeling needs. In addition, Print on Demand complies with all relevant food contact legislation, including the Food Safety Modernization Act. Sinclair Systems International LLC, Fresno, Calif. |

John Deere 2230 Field Cultivator The 2230 Field Cultivator enables producers to efficiently flow residue, leave a smooth seedbed and cover more acres per day. These implements operate at depths of 0-5 inches and come in floating hitch or Level-lift frame configurations, including a new 5 section Level-Lift frame. The floating hitch maintains consistent depth while traveling over uneven ground, while the Level-Lift is designed for flat or gently rolling terrain. Operators can cover up to 217 more acres per day than with the previous model thanks to 8% wider working widths of up to 69.5 feet, 25% faster working speeds of up to 10 mph and no daily maintenance. Each rear harrow in the ProFinish Leveling System is compatible with all implement configurations and rolling baskets have full hydraulic control. Compact transport dimensions are provided with the 50 foot Level-lift model that tightly folds to 14.5 feet high by 14.3 feet wide. Deere & Co., Moline, Ill. |

AGCO MTS Maxx Ride Suspension The MTS Maxx Ride feature adds ultra-high capacity shock absorbers to the class-leading and industry-exclusive Mobil-Trac system. Today’s Mobil-Trac system offers the softest track suspension on the market for a two track tractor. This is a key differentiator for the Challenger line of track tractors. However, with a soft ride can come negative side effects, such as excessive pitching and unwanted movements of the machine and implement. The use of ultra-high capacity shock absorbers delivers an unmatched harmony of ride and control in a track suspension system. As a result, MTS Maxx Ride maintains soft track suspension while limiting unwanted movements of the machine. MTS Maxx Ride dampens excessive pitching motion, allowing the operator to feel more comfortable in the field and have more control on the road. MTS Maxx Ride is available on both the MT700E and MT800E series of tractors. AGCO Corp., Duluth, Ga. |

John Deere 2330 Mulch Finisher The 2330 Mulch Finisher enables producers to efficiently size and flow significant amounts of residue and leave a smooth seedbed. Operators can cover up to 127 more acres per day than with the 2310 Mulch Finisher thanks to 22% wider working widths of up to 56 feet, 3 inches. Working speeds of 10 mph and no daily maintenance provide additional efficiency. The 2330 Mulch Finisher features a Level-lift hitch that provides level performance at depths of 0-5 inches. The ProFinish Leveling System includes multiple enhancements across 6 rear harrow options for superior residue handling and leveling performance depending on customer preferences. Coil-tine harrows feature a knock-down tine configuration on the front rank for superior leveling plus tool-free adjustability. The round-bar or flat-bar rolling baskets both feature adjustable hydraulic down pressure with in-cab control. Larger radial tires provide up to 42% bigger footprint for higher floatation and improved durability. John Deere, Moline, Ill. |

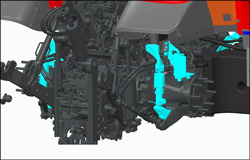

Case IH 4400 Series Corn Head Stalk Roll Spirals The Case IH 4400 Series Corn Head Stalk Roll Spirals are a significant product change that dramatically improves the harvesting capability of the corn head. This spiral technology has been designed to work in concert with the other feeding elements of the corn head row unit to ensure that all of the corn plant is processed and no corn kernels are left behind. The smooth and gradual introduction of the crop to the auger flights, combined with the specifically designed height and pitch of the auger flighting, ensure that all stalks, even when they are lying on the ground, are moved smoothly and gently into the stalk rolls for processing. This feature will be available as standard equipment on all 2017 Case IH 4400 Series rigid and folding corn heads built in Plock, Poland, and can be used on all Case IH combines. Case IH, Racine, Wis. |

John Deere C850 Commodity Air Cart The John Deere C850 Commodity Air Cart increases productivity by seeding more acres per hour with increased accuracy and technology integration. The 850 bushel capacity is provided by four tanks optimally sized to maximize the number of acres seeded between fills. The AirPower 2 dual-blower air system accurately delivers high rates of commodities across the widest drills on sloping terrain while maintaining productive seeding speeds. Individual tank scales and the new ActiveCal system make it easy to calibrate the metering system. A cart-side display provides information on tank scales and tank pressurization and enables cart-side calibration control and bag weight entry. A 100 bushel per minute belt conveyor, large tank lids, hydraulically powered stairs, and spacious platforms reduce seed and fertilizer tendering time and effort. The C850 combines these and many more software and hardware features in an accurate and integrated seeding solution. John Deere, Moline, Ill. |

Case IH Auxiliary Alternator Automation on Early Riser 2150 Front-Fold Planters Case IH Early Riser 2150 Front-Fold Planters now feature Auxiliary Alternator Automation, the first hydraulically driven, auxiliary alternator drive system that uses smart technology to match electrical power generation with demand to minimize hydraulic flow requirements. The need for onboard electrical power varies due to planter size, configuration, target population and ground speed. The new smart alternator drive system auto-detects the machine size, configuration, and components of the system that require electrical power and then uses the target population, ground speed and work status to set the proper Auxiliary Alternator operating speed. In this way, operating efficiency and power demand are matched for optimal hydraulic power efficiency, resulting in reduced cost of operation. Until now, auxiliary power systems have been sized and driven to constantly supply the highest electrical demand possible for a given machine, resulting in increased fuel consumption when maximum power is not required. Case IH, Racine, Wis. |

Case IH Extended-Wear Rotor Inlet Transition Cone on Axial-Flow 240 Series Combines The new extended-wear rotor inlet transition cone on Case IH Axial-Flow 240 Series combines provides farmers and custom-harvest operators with a robust harvesting component that has nearly three times the expected wear life of the original cones and is included in the base combine. While being able to handle ever-higher throughput and capacity, modern combines are challenged with the wear that comes with harvesting crops with high rates of material other than grain (MOG) and more abrasive crops such as rice. The cone transitions the linear flow from the feeder house to a helical path before entering the threshing chamber. The new extended-wear cones are manufactured using a marquench heat treatment process that makes the steel even more resistant to abrasion and wear, saving customers expensive downtime and repair/replacement costs. The extended-wear cones are standard equipment on all Axial-Flow 240 Series combines, including models 7240, 8240 and 9240. Case IH, Racine, Wis. |

Case IH Rowtrac Carrier System on Riser 2160 Rowtrac Front-Fold Planters The Rowtrac Carrier System for the new Case IH Early Riser 2160 Rowtrac Front-Fold Planter represents an industry first, three-axis steerable track solution for a planter to provide increased flotation and a smoother toolbar ride vs. wheeled carriers. The Rowtrac system is the only towed-implement track undercarriage that is pivotable about three major axes for pitch, roll and yaw movement, thereby allowing the track system to be steered while it simultaneously undulates to follow terrain changes in both the pitch and roll directions. The system allows for equal +/-23 F steering motion while simultaneously allowing the track belt to follow the ground contour without impacting steering angle changes. Depending on the planter row spacing configuration, operators may choose the Rowtrac Carrier option with either 88 or 120 inch centers and with either 18 or 24 inch belt widths. Case IH, Racine, Wis. |

New Holland CX/CR Combine with Everest 20 Leveling System New Holland CX/CR Combines with the Everest 20 Leveling System give operators a new way to experience flagship combine technology in extreme hilly conditions. The I2J Everest 20 Leveling System is a stand alone kit that converts the harvester from a standard combine into an expert hill climbing machine, while providing the advantages of operator comfort and harvesting capacity. To achieve self-leveling of the combine, the system commands each traction wheel separately by means of a hydraulic cylinder. Together with a dual-axis inclination sensor, the machine is kept level with a closed loop control algorithm during lifting and tilting, which in turn keeps the combine stable during harvest operations in all circumstances. This greatly improves the combine capacity due to optimized cleaning, threshing and feeding while providing operator comfort, machine stability and safety on steep sideslopes. Operators can manage the system with a user-friendly interface in the cab. CNH Belgium N.V. & I2J Solutions, Zedelgem, Belgium & St. Sulpice, France |

John Deere AutoTrac Vision & AutoTrac RowSense John Deere AutoTrac Vision and AutoTrac RowSense guidance systems provide assistance to AutoTrac that enables the sprayer to follow the actual planted crop row in post-emergence applications. RowSense keeps the sprayer tires between the rows during late-season application, while Vision guides the sprayer during early application. The two solutions allow operators to spray up to 15% faster in-row while reducing operator fatigue over manually driving, resulting in greater productivity and increased versatility. For producers, the systems keep the wheels in the row up to 30% better than manually driving, reducing crop damage. Advanced camera imaging and processing units and tactile sensors are used for sprayer position identification. The new systems work with vehicle auto-steering system, complementing existing GPS-based positioning system by providing accurate relative location to crop rows. AutoTrac Vision and RowSense have proven to meet customers’ needs for spraying performance. John Deere, Moline, Ill. |

New Holland IntelliBale ISOBUS Class 3 Tractor and Baler Automation for Roll-Belt Series Round Balers The New Holland IntelliBale ISOBUS Class 3 Tractor and Baler Automation system provides automated control of the tractor stop, bale wrap and bale ejection cycles on New Holland Roll-Belt Series round balers. The system reduces operator fatigue by eliminating repetitive arm and leg movements that are normally required to control the tractor and baler functions. Productivity is improved by optimizing the tailgate raise and lower cycle times for each bale automatically. Using ISOBUS communication protocol, the baler sends commands to the tractor that control the tractor stop, wrapping of the bale with net wrap, and activation of the tractor hydraulic remotes to raise and lower the tailgate, without requiring any inputs from the operator. The IntelliBale option is compatible with ISOBUS Class 3 equipped New Holland T6 and T7 Series tractors with AutoCommand continuously variable transmissions and with T7 Series tractors with PowerCommand full powershift transmissions. New Holland Agriculture, New Holland, Pa. |

CNH Industrial SmartTrax with Flex Technology for New Holland CR Combines SmartTrax with Flex Technology for New Holland CR Combines gives producers a new, economical way to experience the benefits of using tracks as an alternative to tires. This optional equipment offers an alternative to traction tires to reduce ground compaction and improve operator comfort. The track units use the same triangle design and ground-following behavior as the New Holland SmartTrax with Terraglide suspension system, yet cost considerably less due to the new design using rubber strut suspension rather than hydropneumatic suspension. Operators choosing SmartTrax with Flex Technology can ride comfortably and safely at road speeds up to 19 mph and benefit from a 60% reduction in ground compaction compared to combines with tires. Double-hinged rollers in the tracks maximize the contact surface between track and ground and reduce stress on the track belt and roller, resulting in longer belt life. CNH Industrial Belgium N.V., Zedelgem, Belgium |

Post a comment

Report Abusive Comment