Editor’s Note: This Q&A originally appeared in AG Tire Talk to provide answers that farm equipment dealers have about farm tire technology. This series features a trending question followed by an abridged version of the answers. For the complete answers, check out www.agtiretalk.com.

Question: If producer is working fields with +11° Slope (+20% Grade), what changes should be made in tire selection (Bias-Radial-IF/VF CFO), air pressure, and operator procedures to ensure optimum performance and minimal downtime.

Note: AG Tire Talk recommends that you consult with tire manufacturers before proceeding with any steep slope agricultural tire adjustments discussed in this article. Please see end of article to view a complete list of tire manufacturer contact information for companies that participated in this installment of AG Tire Talk.

Ag Tire Talk Key Takeaways

Michelin: First, let’s understand why choosing the right tire at the correct pressure, as it relates to +20% grade, is important. Tires with inadequate inflation could potentially allow the lateral force to roll a tire right off the rim.

Maxam: The three primary reasons to increase cold inflation air pressure when in sidehill or hillside operations:

1. Improved tire seating on wheel – provides stronger bead seating pressure against the flange of the wheel (seating pressure).

2. Increased air reduces sidewall flexing as weight transfer occurs as the tires work up or down / or travel laterally across a hillside (weight transfer).

3. Ensure vertical footprint pressure pushing tread band onto the operating surface (traction).

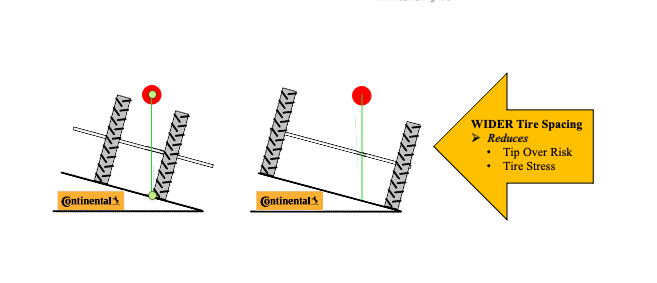

Continental: TRA and its European counterpart ETRTO define a clear borderline at an 11° slope (20% grade). Is it black and white? I would rather take it as a clear orientation point from which more caution needs to be paid towards the topic.

Precision Inflation: For +20% grades, most farmers should seriously consider a hillside combine option that levels the machine for better threshing and machine stability. For grades up to 20%, although Tire & Rim Association doesn’t mandate, I recommend raising tire pressures+ 6 psi above tire manufacturers’ load/inflation table minimum to provide additional tire protection- checking with Tire Dealer to make sure it’s within maximum allowable limits.

BKT: If radial tires are used with recommended air pressures for normal farming, they provide low lateral stability on the hillside. Air pressures must be adjusted up to take out some of the sidewall flex to keep the tire from rolling off the wheel on the steep slope. Increased air pressures also help with stability and prevent rollovers on steep slopes.

Trelleborg: When the application surpasses the 11-degree slope mark, the tires suffer a lot of sidewall stress that could damage the tires, create unstable lateral movement and be the cause of potential tire/rim unseating. To prevent this situation, several steps must be considered. Increase the recommended inflation pressure for normal conditions by 0.5 bar (7 psi)- the inflation pressure can be increased up to +25% without surpassing the maximum nominal inflation pressure of the tire. No load bonus below 20 mph (30 km/h) on non CHO/CFO tires. Cyclic bonus does not apply on CHO/CFO type tires.

Yokohama: Tread pattern is also important on hillsides…the hybrid tread doesn’t dig into the ground on hillsides like R-1 lugs do, so they experience less slip and better efficiency and fuel economy.

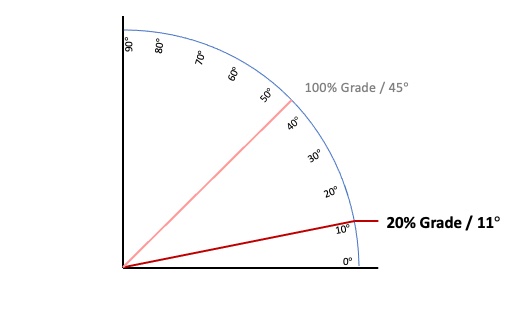

The above illustrates an 11° (20% Grade) slope.

The above illustrates an 11° (20% Grade) slope.

Blaine Cox, National Product Manager–Agriculture, Golf & Turf, Yokohama Off-Highway Tires America Inc.: Inflation pressure is especially important for farmers operating on steep slopes because of the extreme stress on the tire’s bead area and the need for stability. Too little air can allow the bead to roll off the rim. Too much air prevents the tire from absorbing impact and transfer those shocks to the rest of the machine. If there ever an application for central tire inflation systems, this is it.

It’s important to remember that since putting a machine on a steep angle puts more of its weight on the downhill tires, the usual load inflation tables do not apply. You will need to add five to seven psi over the stated non-slope inflation pressures on slopes that have a grade of 20%, making sure not to exceed maximum allowable pressures. Tread pattern also is important on hillsides.

When it comes to steep slopes, the tire has to be really well-built, including a very strong bead bundle and a sturdy sidewall turn-up to take the added load and stress. And the rim has to be extremely strong, too, especially with a tire that is going to reduce slip and put all that engine torque into the wheel. Every piece of the system has to be up to the challenge.

Harm-Hendrik Lange, Customer Solutions Engineer, Continental Specialty Tires: Normally, the recommendation for agricultural tires is to lower the inflation pressure as much as possible for the lowest soil compaction, the widest footprints and to have as many lugs as possible in contact with the ground for best traction. But to use the load-speed-inflation-pressure-matrix of a tire to the borderline values, tires should not be operated on steep inclines. The TRA defines a clear borderline at an 11-degree or 20% grade.

Combines have quite high grain storage. If the full capacity of the grain tank needs to be used, this can have a very strong impact on the driving stability on steep inclines, but in the same way to the deloading of the uphill tire and the additional load on the downhill tire, with the resulting higher-side (steering) forces on the higher-laden tire. You can imagine that a 15% load bonus for cyclic harvest operations (CHO) or cyclic field operations (CFO) is quickly eaten up on steep inclines and cannot be taken into account like in level conditions.

If the end user asks for the effect of different types on inclines, the good, old bias tire has a higher sidewall stiffness compared to a radial-type carcass, which may help him to better handle strong side forces. If we compare a traditional radial with increased flexion (IF) and very-high flexion (VF) tires, the same logic applies - the more flexible the sidewall, the more it will deform on slopes as a reaction to side forces.

Agricultural tire manufacturers are clearly listing up to 20% incline in their data books for the practical application of load/pressure tables. If the slope operation exceeds this value, it is advised that you contact the tire manufacturer.

Dave Paulk, Manager, Field Technical Services, BKT USA Inc.: There are different opinions on using bias or radial tires on hillside applications. Some think that the higher air pressures and increased sidewall stiffness of bias tires will provide better stability. Others think that radials will provide better traction. In either case, tires used in this application must provide both stability and traction. And air pressure levels must increase to accommodate.

Caution should be used on sloped areas. Hillside applications can change the center of gravity of the tractor or combine, especially with loads, which increase weight on the downward side and make machines top-heavy. Increased air pressure levels can off-set some of the weight shifts and minimize tire wall separations.

The point at which air pressures and hillside stability become crucial seems to be the 11-degree slope or 20% grade. The Tire & Rim Association (TRA) handbook lists load carrying capacities and speeds up to this point before referring to manufacturers’ recommendations. There are some TRA load and inflation charts that include hillside combine applications, but load adjustments and increases below 20 miles per hour do not apply.

Radials are becoming more prevalent in hillside applications on both tractors and combines. Radials, by design, have a flatter, larger footprint than bias tires and provide good lateral traction. If radial tires are used with recommended air pressures for normal farming, they provide low lateral stability on hillsides. Air pressure levels must be adjusted to take out some of the sidewall flex in order to keep the tire from rolling off the wheel on the steep slope. Increased air pressure also will help with stability and prevent roll-overs. It is generally recommended to add six psi over the recommended air pressures for tractors operating at a 20% grade on hillsides.

Greg Gilland, Vice President, Global Agricultural Program, Maxam Tire International: The cold inflation pressure or air pressure management is the key to optimizing how a tire will perform on any piece of equipment, at any speed and load and on any surface application. Hillside applications require some adjustments to cold inflation pressures to allow radial tires to deliver optimal performance because of the exceptional forces working on the tire.

The three primary reasons to increase cold inflation pressure when in hillside operations are improved tire seating on the wheel, which provides stronger bead seating pressure against the wheel’s flange; a reduction in sidewall flexing as weight transfer happens when tires work up or down - or travel laterally across - a hillside; to help ensure vertical footprint pressure, pushing the tread band onto the operating surface.

The challenge is recognizing the impact of the hillside or grade level and what off-sets should be considered in the effective and safe performance of equipment. The impact of the grade or “steepness” has to be accounted for to ensure that the tire’s cold inflation pressure is adjusted to meet the additional forces - such as seating pressure and weight transfer - when operating on any hillside.

Norberto Herbener, OE Applications Engineer, Trelleborg Wheel Systems: When the application surpasses the 11-degree slope mark, the tires suffer a lot of sidewall stress that could damage the tires, create unstable lateral movement and be the cause of potential tire/rim unseating. To prevent this situation, several steps must be considered:

- Increase the recommended inflation pressure for normal conditions by 0.5 bar (7 psi). The inflation pressure can be increased up to +25% without surpassing the maximum nominal inflation pressure of the tire.

- No load bonus below 20 mph (30 km/h) on non CHO/CFO tires.

- Cyclic bonus does not apply on CHO/CFO type tires.

Ken Brodbeck, VP of Technology Precision Inflation, LLC:

SIDEHILL +11° Slope (+20% Grade) Tire Adjustments

Adjust Tire Pressure As Necessary

Whether you farm along terraces or go up and down hilly fields, your tires will see higher vertical and lateral loads than on flat fields.

Traction and flotation also can be critical in wet hilly conditions.

What should you do?

Combines / Tractors:

- For +20% grades, most farmers should seriously consider a hillside combine option that levels the machine for better threshing and machine stability.

- For grades up to 20%, although Tire & Rim Association doesn’t mandate, I recommend raising tire pressures+ 6 psi above tire manufacturers’ load/inflation table minimum to provide additional tire protection- checking with Tire Dealer to make sure it is within maximum allowable limits.

- For +20% grades, I recommend calling the tire manufacturer.

- Increasing pressure for all grades will reduce lateral sway and improve stability.

- Choosing optional larger tire size will increase load capacity.

What should you do if you have both flat AND hilly fields?

Adjust pressures depending on the field condition.

Without an “On the Go Inflation System” you are going to be stuck at one pressure because NO ONE changes 8 tires by hand from field to field.

Precision Inflation, LLC specializes in systems that allow you to adjust your tire pressures to the conditions you need:

- Changing axle loads with front fold planters

- Changing from pull type to fully mounted implements

- High speed transport for manure and spraying operations to low-speed field work.

- Simply being able to check and adjust your tires every day to keep them at their optimum field and road pressure provides a huge return on investments

Remember, Pressure Matters!

David Graden, Operational Market Manager, Agriculture, Michelin North America Inc.: Regardless of slope, I would always lean towards recommending radial tires to maximize machine performance and minimize downtime. There is a rule of thumb that Michelin uses and publishes in our data book as a recommendation for a 20%-plus grade.

With regard to air pressures and making pressure recommendations, we typically assume an average of up to 12% weight shift across all axles. Simply put, we take the weight of an axle and divide it across all tires plus-12% to account for this potential increase in load per tire as it moves over varying terrain.

When a producer operates in a field with slopes at 20% grade or more, safety and stability become a concern. If tires are not properly inflated, they may not be able to withstand the added weight and lateral stability and become compromised. For a 20%-plus grade, machine weight will transfer about 30% to one side. For this reason, we publish a standard recommendation of plus-6 psi.

As the slope gets more severe and the weight shift reaches 35% to 45%, we highly recommend consultation with the tire manufacturer for air pressure recommendations and corrections. Further, these recommendations may not exceed maximum allowable pressures, which, if exceeded, may require another solution. It is vitally important to know and check equipment air pressure levels frequently. If a machine will operate on a slope of 20% or more, this is even more important.

For Steep Slope and other Manufacturer technical information, please contact the following, or look up on www.agtiretalk.com

BKT USA Inc.

Dave Paulk

(330) 836-1090

Continental Specialty Tires

Dana Berger

dana.berger@conti-na.com

Maxam Tire North America Inc.

(844) 629-2662

marketing@maxamtirena.com

Michelin North America Inc.

www.agricultural.michelinman.com/us/contact-us

Yokohama Off-Highway Tires America, Inc.

Blaine Cox

(205) 910-8101

bcox@yokohama-oht.com

Trelleborg Wheel Systems

www.trelleborg.com/en/wheels/tools-and-resources/agriculture-and-forestry-tires/technical-information

View complete article at www.agtiretalk.com

Post a comment

Report Abusive Comment