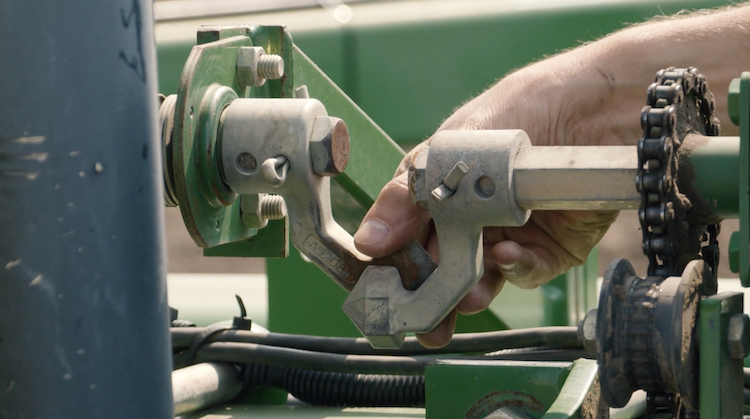

Pictured Above: MECHANICAL INSPECTION. Worn, stretched or seized drive chains can lead to skips, doubles and other spacing errors at planting.

INEXPENSIVE UPDATE. Chains are fairly inexpensive, so in many cases it makes sense to simply replace them annually.

At 13 plus seeds per second moving through the field, it’s critical to try to eliminate vibration on your planter’s drive system. Vibration caused by mechanical components like chains and sprockets can take a properly performing meter and cause it to create skips, doubles, and spacing errors.

Be sure that any chains and sprockets are working well. Chains should be properly lubricated. Replace chains annually, they’re fairly inexpensive.

You also want to check the sprockets themselves. If the teeth on the sprocket begin to wear that’s going to create chatter and accelerated wear of the chain, which affects seed meter performance.

CHECK THE SPROCKETS. Worn sprockets can create chatter and accelerate wear on the chain, which in turn affects seed meter performance.

Check any tensioners and idlers. If you see that an idler has wear in it, this can create vibration in a chain and cause it to walk back and forth. You’ll want to replace that idler.

Remove the drive chain from the hex shaft on the planter. Put a wrench on the hex shaft and rotate it and feel for any grinding that may occur. If it doesn’t feel smooth you’ll want to pull the hex shaft out and check to ensure that the bearings themselves are spinning smoothly. If they’re not, be sure to replace them.

WORN IDLER. Replace the idler if it shows signs of wear. A worn idler will cause vibration in a chain and cause it to walk back and forth.

When you go to replace the bearings another important thing to check is that any hex shaft sections on your planter are aligned properly. Improper alignment can cause a section of the rows of your planter to have a loping characteristic to them. This means that the population will go high and low and high and low as the alignment of those drive dogs begins to change as you go through the field. Check at each fold point or shaft transition point on the planter.

If your planter has a cable drive you’ll need to disconnect the cable drives and inspect the ends to ensure there’s no fraying. Fraying on the ends of the cable drives can create vibration and a poor rotation of the seed meter. This will also result in poor spacing down to the ground.

These maintenance items take quite a bit of time, but they’re things that you can check in the offseason. If you catch these errors before you go to the field it’s going to save you a tremendous amount of downtime or regret from a poor stand in the coming season.

Watch this video about checking the planter's drive system.

A Premier Precision Planting Dealer is your partner to help you achieve a picket fence stand this spring and steer clear of the regret that comes from avoidable yield loss caused by lack of maintenance. Find your local Precision Planting Premier Dealer at PlanterExpert.com.

To watch videos of all recommended annual maintenance checks, visit PrecisionPlanting.com/Maintenance.

Download the free Planter Maintenance Guide. Included in this guide is a 1-sheet checklist, links directing you to the corresponding videos, and an overview of 15 key maintenance areas on your planter.

The Planter Maintenance series is brought to you by Precision Planting.

For farmers who believe in better. Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.

Post a comment

Report Abusive Comment