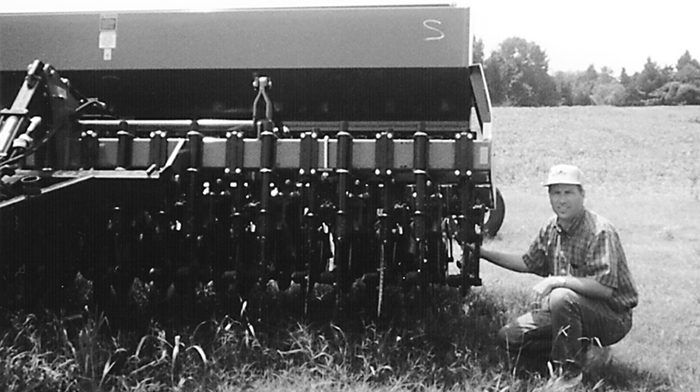

A John Deere Enthusiast, Allen Verell wasn’t sure what to expect from the United Farms Tools (UFT) 5300 no-till drill that he won use of for a year at the 1998 National No-Tillage Conference.

“I’m a John Deere person,” says the Jackson, Tenn., no-tiller, who owns a 750 drill, “but the United Farm Tools drill met my expectations. It was easy to set up, didn’t need any repairs and provided a good stand.”

At the National Farm Machinery Show in Louisville, Ky., Verell told the UFT representatives how he he wanted the no-till drill equipped.

“They gave me exactly what I asked for,” he says. “The color was even right—green, of course!

“They also checked back with me to make sure everything was OK. They meet their promises.”

Verell’s 15-foot drill came equipped with double-disc openers and bubble coulters. He explains that he prefers bubble coulters to wavy coulters soils because they pick up less dirt.

Easy As 1, 2, 3

When Verell took delivery of the drill at his 2,200-acre corn, soybean and cotton farm, he spent some time reading through the owner’s manual, then went to work setting up the drill for bean planting.

“The United Farm Tools drill is set up differently than the John Deere,” he explains. “With common sense and reading through the owner’s manual, we got the drill adjusted in just 20 minutes. It ran smoothly and we never had to make another adjustment.”

Ideal Conditions

Verell was also impressed with the drill’s seed placement and its ability to penetrate the ground. Conditions during May soybean planting were optimal, he says.

“There was good soil moisture; the seed germinated real quick,” Verell recalls. “Beans were up in less than a week.

“We put down 70 pounds of beans per acre and set the drill to plant 1 to 1 1/4 inches deep. The coulters and double-disc openers provided excellent penetration.”

Verell was able to plant 85 acres a day at 6 mph. By the end of the season, the drill had covered 350 acres.

Neighbors Get A Turn

Verell’s neighbors were also very thankful that he had such good luck at the National No- Tillage Conference.

“The neighbors got their chance with the drill, and no I didn’t charge them for it,” he laughs. “The drill worked real well for them.”

Top Model

Verell explains that the UFT 5300 drill is the best drill the company makes. An update from the 5200 series drill, the 5300 is designed specifically for no-till.

While the 5300 series is as rugged and durable as earlier versions, it has several upgrades, including an expanded rear walkway, strengthened hitch, digital acre counter and an optional 3-by-13-inch, single-rib press wheel to give depth control while closing the seeding trench and firming the seedbed.

One feature Verell particularly liked about the UFT drill was the hydraulic weight transfer system. This system adds 1,500 pounds of the tractor’s weight to the weight of the drill.

The goal of the weight transfer system on the drill is to provide good soil penetration in no-till’s tough terrains. Verell says this system made adjusting to different soil quick and easy.

So What Does He Prefer?

Looking ahead to his next drill purchase, Verell says he may consider a UFT.

“I can’t say that one is better than the other,” says Verell. “I honestly liked the stands I had with United Farm Tools drill, but the John Deere produces very good stands, too.”

Post a comment

Report Abusive Comment