Most planters have a “weight problem,” says Michael Musselman, vice president of sales and marketing at Martin Industries, a leading supplier of no-till and conventional-till planter attachments.

Excess weight in the center of a planter or improper weight distribution often leads to yield-robbing compaction, shallow or inconsistent planting, and reduced plant vigor. In addition, the natural reduction in weight that occurs during planting contributes to the problem of down force fluctuations that can negatively impact the accuracy of seed and fertilizer placement. Irregular soil tilth, wet conditions and bumpy or rolling terrain can also wreak havoc with planting accuracy, resulting in uneven emergence and inconsistent stands.

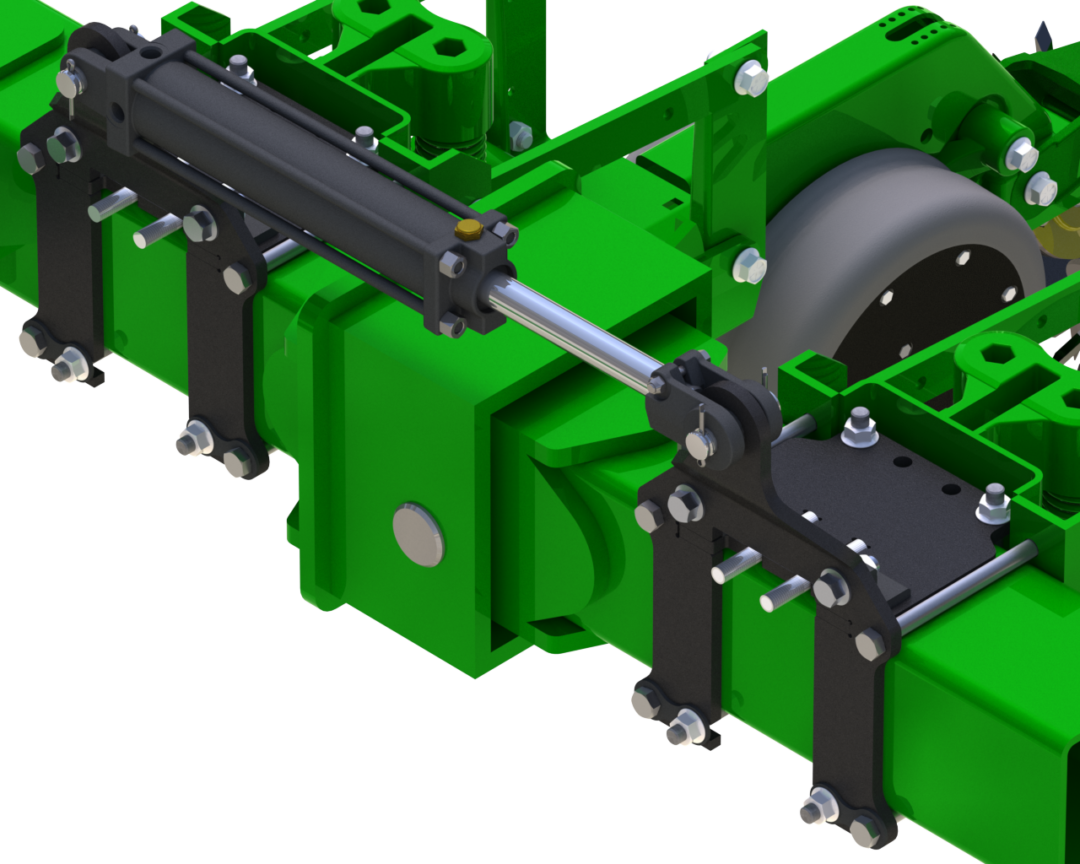

Martin Industries’ innovative new Martin-Till Weight Transfer System (WTS) addresses this weight problem by redistributing excess weight from the center of the planter to the wings. Keeping the wings level and the row units in the ground will keep planting depth consistent through changing conditions.

Benefits of the Martin-Till WTS include:

• An in-cab control box which allows for easy adjustment as you plant

• The patented bolt-on bracket design requires no welding and is easy to install

• The hydraulic control kit provides durable and quick adjustment

• The mounting bracket allows for frame-mount nitrogen coulter installation

The Martin-Till WTS will be released at the Farm Progress Show in Decatur, Il., this August 27-29 and will be available for 12- and 16-row 1770/1790 Model John Deere planters for the 2020 planting season.

For more information, visit www.martintill.com or contact Michael Musselman at michaelm@martintill.com.

Post a comment

Report Abusive Comment