No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

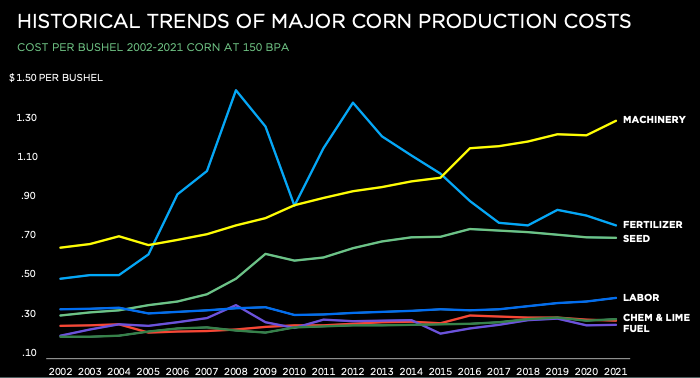

Figure 1. Data from the USDA show machinery costs steadily rising from about $0.65 per bushel of 150-bushel corn in 2002 to about $1.20 per bushel of corn in 2022. Other production costs, such as seed and fertilizer, have not shown the same sustained increase over the last 20 years. Source: USDA NASS as of September 2022

As farm machinery costs increase far beyond the rate of inflation, making a new machine pencil out may require some creative thinking about its potential uses and how farm operational expenses will change in the next decade

Clay Mitchell, no-tiller and co-founder of farmland venture capital firm Fall Line Capital, says machinery costs have skyrocketed in the last 10-15 years. USDA data show machinery costs steadily rising from about $0.65 per bushel of 150-bushel corn in 2002 to about $1.20 per bushel of corn in 2022 (Figure 1).

Machinery costs increased at more than twice the rate of inflation, and they’ve also increased more persistently than seed, chemical and fertilizer price increases. Mitchell says machinery costs are going up on a per acre and per bushel basis, even though yields have only increased 1.5% per year or less in the same amount of time.

“In other areas of automation, you have this massive decrease in cost per performance, but somehow in farm machinery you don’t,” Mitchell says. “I'm not pointing fingers here, but I see it as an opportunity. Something's gone wrong, and you get less and less for your money every year.”

One way to get more machinery for the money is cheaper machines, but another option is to use machines for multiple applications, including harnessing data in different ways. Mitchell’s farm in northern Wisconsin uses a Case IH Titan 4530 floater to spread crushed rock with a high silica content on fields. The…